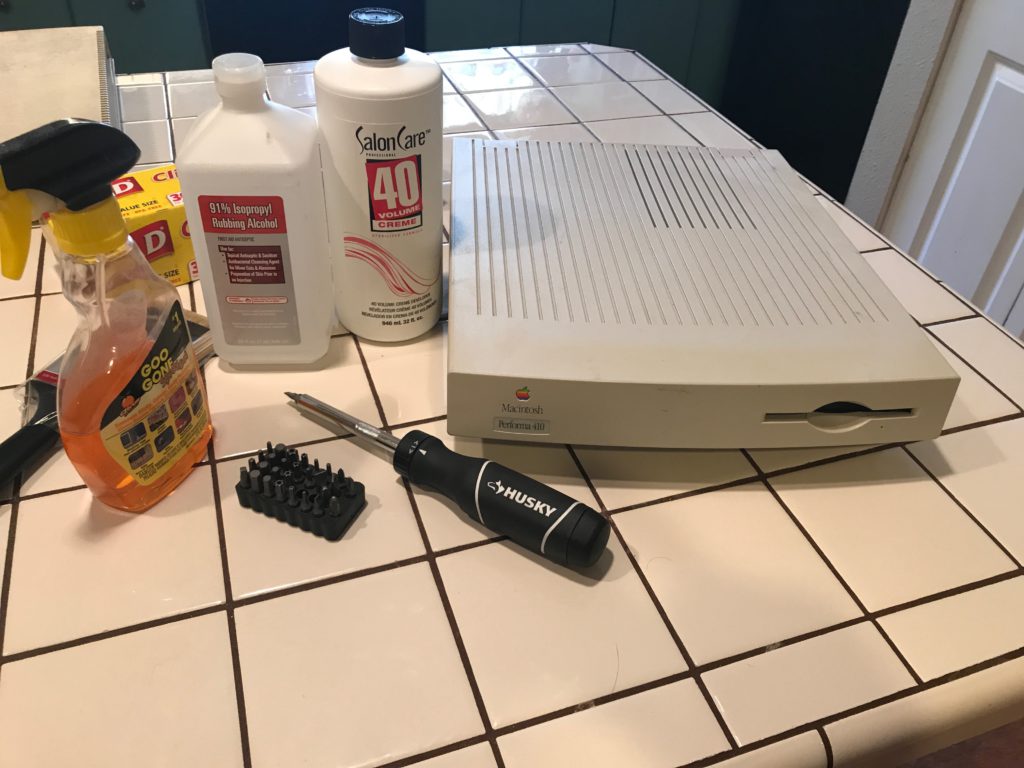

This Performa 410 came cheap on eBay a few years ago. I have always loved this form factor of Apple computer. Small, quiet, cute, charming. I used to have a number of LC and Performa machines, one of which (a Performa 475) was quite decked out and used in my kitchen to manage recipes, participate in the occasional chat, and other such things. That machine had a 15″ monitor attached, an Asante PDS Ethernet card, an external ZIP-100 drive, and System 7.5.5. It ran the iCab web browser. Due to my stupidity in the mid-2000s, I no longer have those machines or many machines from my old collection. I’ve been slowly rebuilding–not cheap today like it was then. The Performa 410 is slated to re-take the kitchen computer role, once it is all restored.

It has the following specs:

- 16MHz 68030 CPU

- 4MB RAM (max 10MB)

- 80MB hard drive (possibly non-functional)

I have System 7.5.5, and still own the Zip drive from the old Performa 475. Here begins the restoration! Following are a few photos of the sad state of this machine before I began:

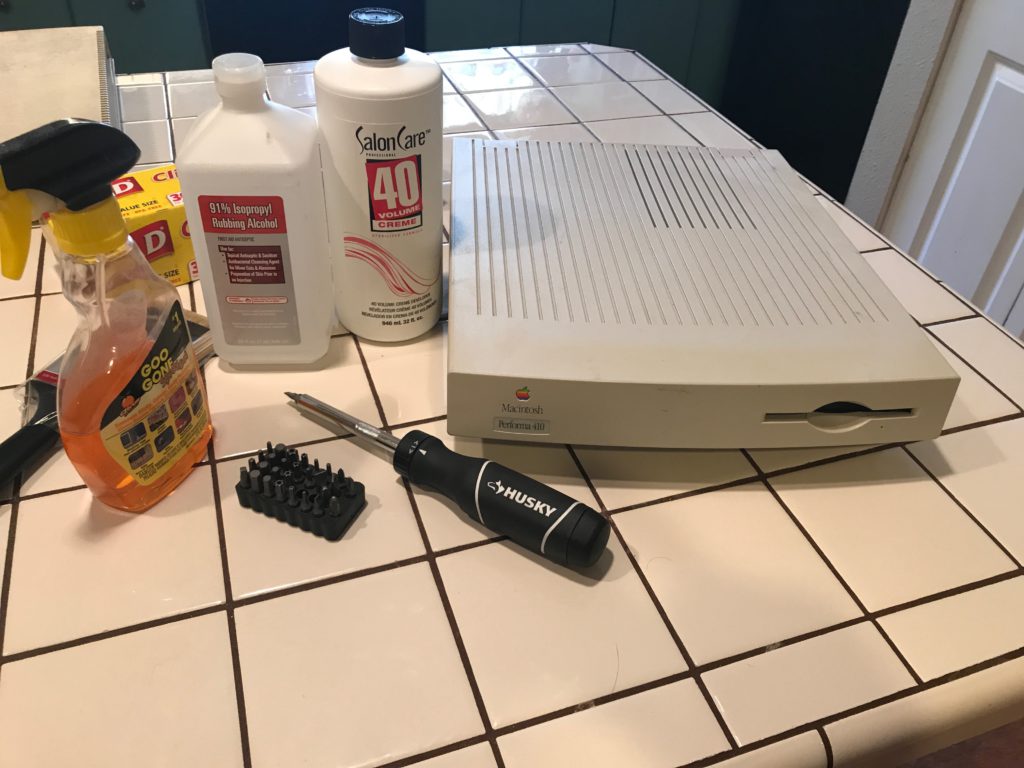

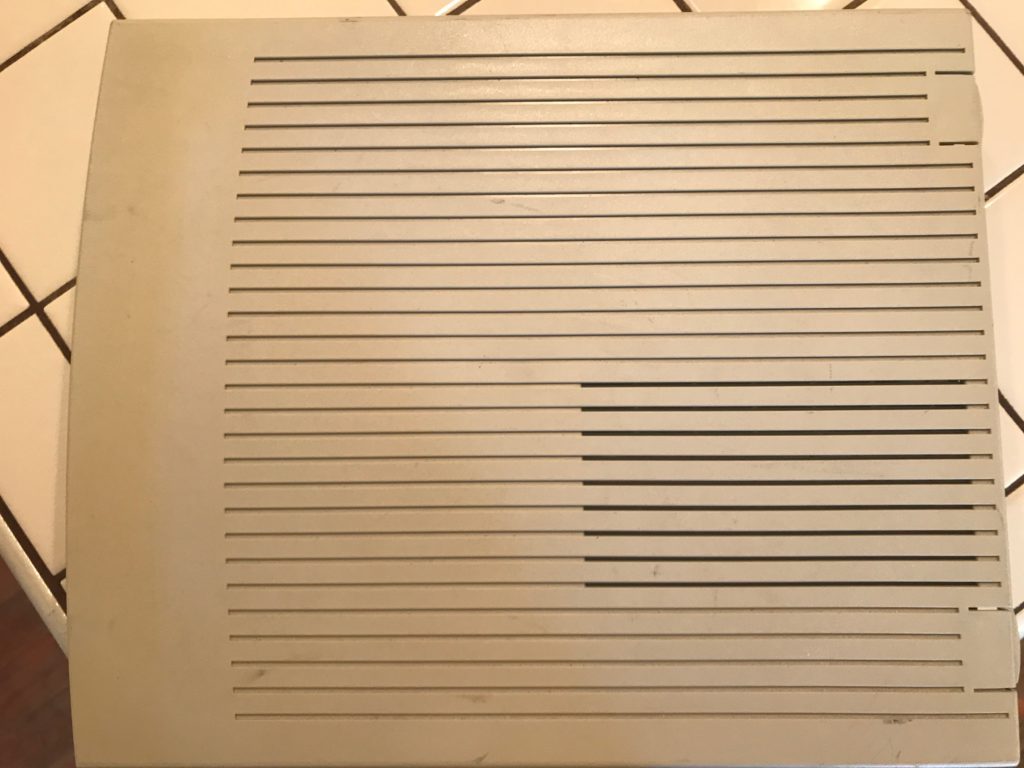

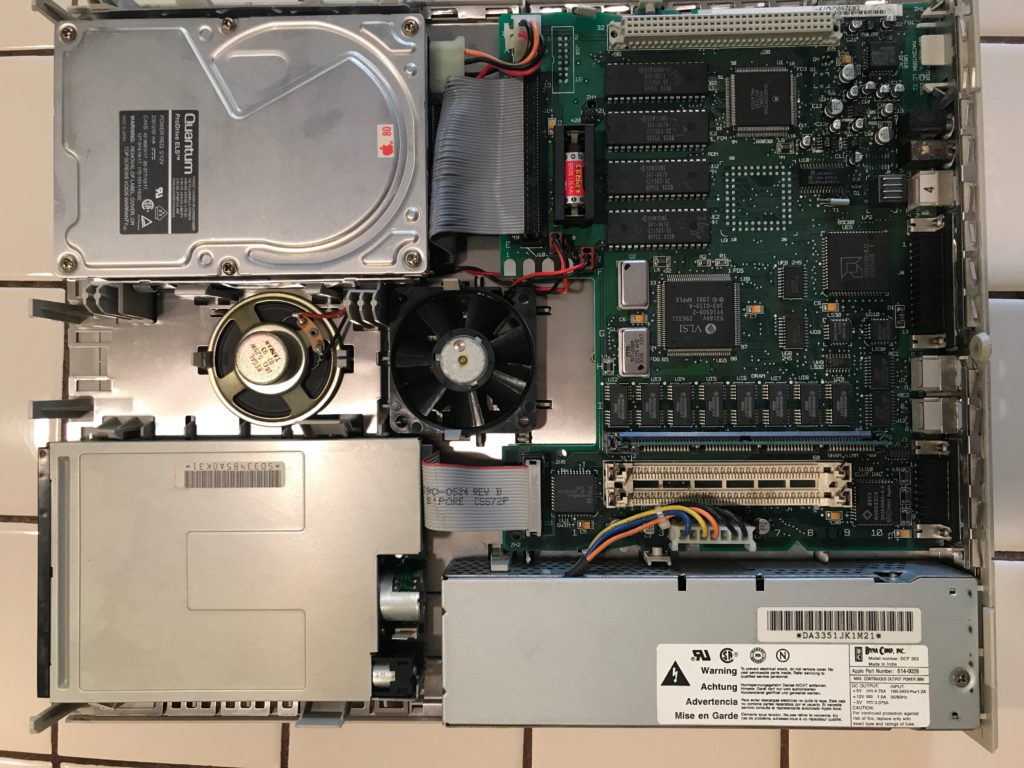

It’s filthy and yellow. The inside is extremely dirty. I began by removing the outer casework and cleaning up the inside:

After taking this photo, I removed and discarded the 3.6V 1/2 AA lithium battery, which was heavily corroded on the positive end. Miraculously, the corrosion had not spread beyond the positive contact of the battery holder, which itself wasn’t even that bad. I applied vinegar to the positive contact of the battery holder to neutralize the small amount of corrosion, then cleaned it with 91% isopropyl alcohol. A replacement battery is on order, and I have a 12″ Apple RGB display to go with the machine.

Here is the outer casework after initial scrubbing with soap and water, using 91% isopropyl to work out the tougher marks:

Next up, I needed to take care of the yellowing problem. This is caused by flame-retardant materials in the plastic reacting with ultraviolet light. The solution is to soak the plastic in a strong hydrogen peroxide and, ironically, expose it to UV light. Thanks to the advice of YouTuber The 8-Bit Guy, I use Salon 40 cream developer, which is about as close to a pre-packaged retr0bright solution as you can buy.

Here’s the machine covered in the solution and wrapped in plastic wrap to keep it from evaporating in the sun:

After sitting outside for approximately four hours, here is the final result:

As you can see, the machine looks nearly new, and ready to begin its new life! I will post an update as soon as the machine is actually up and running.

I do not approve of this usage of my original images for an apparently AI-generated article without my permission or credit. Remove the stolen images and the link to my article immediately.